Moses Kimotho is a well-rounded student at Ship who exemplifies what it means to go after the opportunities in front of him. He is a junior mechanical engineering major, historian for Alpha Kappa Psi, aircraft hydraulic systems craftsman for the Air National Guard and works as a mechanical engineering intern at Burnside America. Kimotho joined Burnside in the fall of 2023 and since then he has come a long way with the company.

Burnside America is a leading manufacturer of custom hydraulic cylinders. Located in Chambersburg, Pennsylvania, Burnside is the North American subsidiary of Burnside Autocyl, an Ireland-based company well-known for its hydraulic solution. While at the company, Moses has gained hands-on experience that has not only improved his engineering abilities but also given him a unique perspective on the business side of manufacturing.

Burnside America was founded in 2014 and has played a huge role in supporting equipment manufacturers across North America. Burnside prides itself on offering customized solutions and utilizing the latest and best manufacturing techniques. According to Angela Morrissey, operations manager at Burnside, their mission is straightforward: “Our culture has always been to understand and prioritize our customer needs above all else. We offer a complete service, from bespoke design to state-of-the-art manufacturing, logistics management, and aftermarket support.”

Kimotho was recruited to Burnside through a Shippensburg University internship and job fair. Morrissey, an alumna of the university, highlighted the importance of harnessing connections with students. Having the opportunity to experience real-world scenarios while still being in a learning environment allows for growth and development in so many ways,” she said. “As the employer, it allows us to provide that opportunity while benefitting from a well-rounded employee.”

In addition, Kimotho shared how the small size of Burnside America has allowed him to form a stronger understanding of the operations. “My primary responsibility has been to directly support the plant manager, Tony Morrissey, in every way beneficial to both Burnside as well as myself,” he said. “Because of the size of Burnside, I have been presented with a lot of different challenges that have made me a better engineering student.”

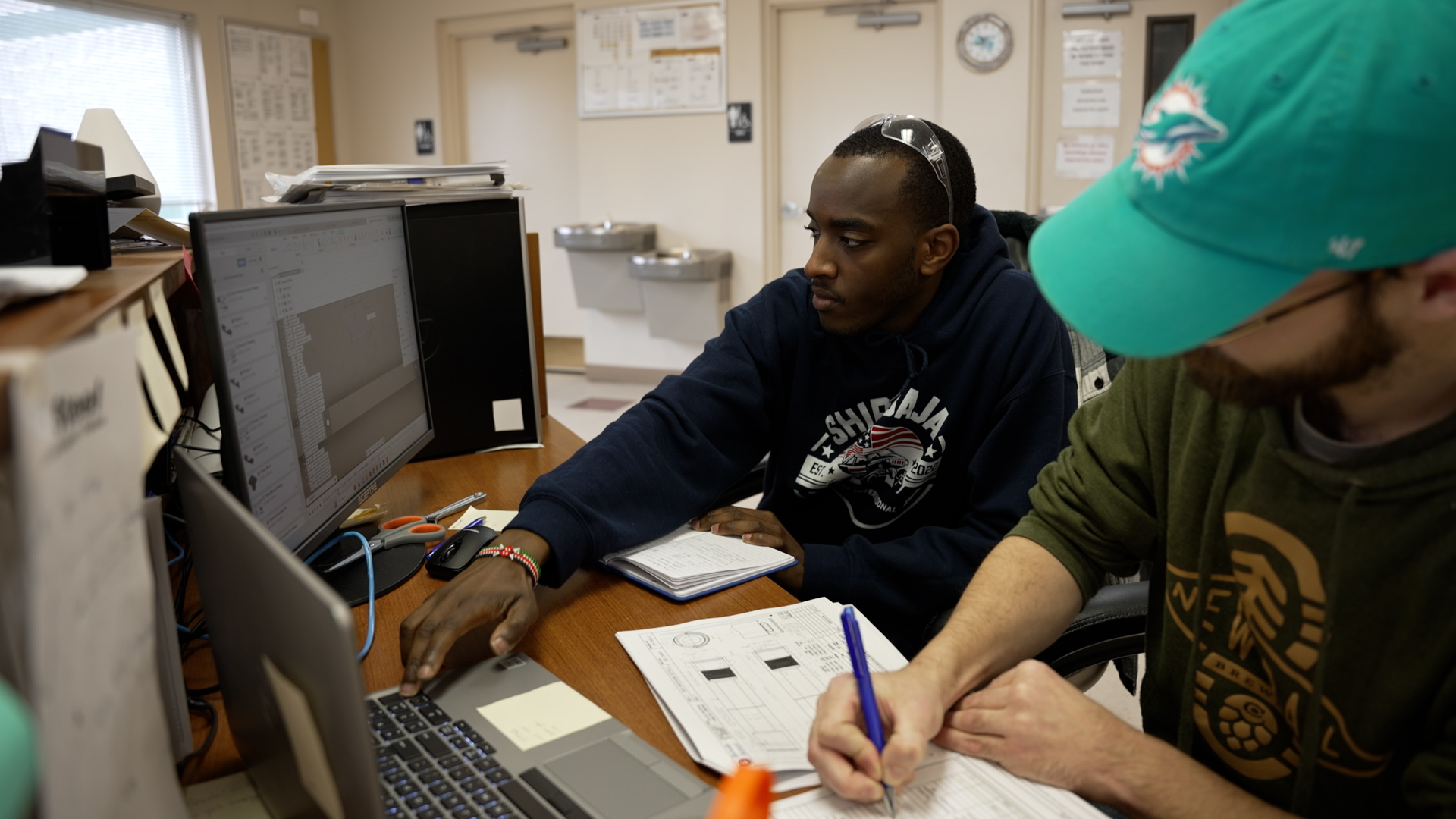

One of the challenges that Kimotho faced involved designing a weld fixture for a new hydraulic cylinder as a part of the company’s production line expansion. Moses and another intern worked together to create the cylinder, following a blueprint reader and CAD software to create the design.

Kimotho also measured and created layouts for the expanded manufacturing space, which served as an important step in planning for the new production machinery. Also, he worked on an inventory of custom tooling used in the assembly areas, containing 3D models the simplify the creation of future replacements.

These projects helped Kimotho gain valuable technical and problem-solving skills, especially in CNC machining. CNC machining allows for the high-speed creation of a part, essentially by using a robot controlled by written code to cut and shape parts in any way one may desire,” he said. “It has let the creative side of my brain run wild when we are tasked with designing parts and fixtures.”

The internship has also helped Kimotho learn the important aspects of business, human resources, sales and planning. “Working with Burnside America has shown me that as an engineer, you will have to key into the side of business that is outside of your school-taught expertise,” he said. “You need to be personable enough to build a welcoming work environment but also firm enough to uphold the company’s values.”

Morrissey acknowledged that internships are both valuable to students and employers, highlighting that Kimotho brought a lot of new ideas and perspectives to the company. Having engineering students who can come on-site to work on projects and be hands-on gives us the opportunity for feedback on new ways they are learning things and new technology they are working with,” she said.

Kimotho’s work at Burnside and ability to balance his internship with his many other responsibilities is both inspiring and motivating. “Not every project needs a groundbreaking, NASA-level solution,” he said. “Often, the quicker you reach a simpler solution, the easier it becomes to scale it up or down as needed.

Burnside America is committed to encouraging young and ambitious professionals to join its mission. Kimotho’s experience with the company has been invaluable in shaping his future career path. Through hands-on projects and mentorship, he has gained a stronger foundation that will help him succeed as a mechanical engineer.